Stretch Wrap Information

Stretch Wrap– A highly stretchable plastic film commonly made from Linear low-density polyethylene (LLDPE) wrapped around items. The elastic recovery keeps the products tightly bound.

Stretch film is used to wrap products on pallets and secure them to each other and the pallet. Helping to reduce product loss, discourage load tampering, and reduce worker injury.

We explain in further detail in our blog post What is stretch film used for. There are a variety of widths, thicknesses, and types of stretch film.

Below is a breakdown of the two most commonly used extrusion processes of stretch film. Extrusion is the manufacturing of stretch film and a variety of other flexible plastic products.

Visit our blog for further details about the extrusion process.

Cast Stretch Wrap– Also called cast stretch wrap, is manufactured using a cast extrusion process.

The Cast extrusion process is a continuous process by which a thermoplastic material is melted and extruded through a flat die onto a chill roll, where it is quenched and re-solidified.

This process allows the Cast stretch film to have excellent clarity, require less force to stretch, increased tear resistance, unwind quietly from machines, and offer a superior cling.

There are both machine grade and hand grade cast stretch film available.

Advantages of Cast Stretch Film- Less expensive than blown stretch film, due to reduced manufacturing costs cast stretch film is more popular.

Increased clarity allows users to see wrapped products. Cast stretch wrap unwinds quietly compared to blown stretch wrap.

Cast stretch film offers two-sided cling that allows the wrap to stay securely packaged.

Disadvantages of Cast Stretch Film– Does not offer the load/holding power blown stretch film provides. Cast stretch film has less memory and tear resistance than blown stretch film.

Blown Stretch Wrap– Also referred to as blown stretch wrap, is manufactured using the blown extrusion process.

This Plastic melt is extruded through an annular slit die, usually vertically, to form a thin-walled tube. Air is introduced from an opening in the center of the die to blow up the film tube like a balloon.

On top of the film tube, an air ring blows onto the film to cool it. This process allows blown film to be more robust and more resilient than cast film.

The higher mechanical properties of blown film typically allow a more significant load holding power.

Advantages of Blown Stretch Wrap– Offers higher load and stretch capacity. Blown stretch film is a premium quality film.

Blown stretch film has a higher degree of memory once stretched, allowing product loads to stay better secured.

Higher tear resistance is an advantage when securing loads with sharp edges.

Disadvantages of Blown Stretch Wrap– Higher cost due to the manufacturing process. The blown stretch wrap has poor clarity due to crystallization in the manufacturing process. Blown film is also noisy when unwound from rolls.

Frequently Ask Stretch Film Questions

When do I use Stretch Film?

Usually, a stretch film holds boxes and products together on a pallet for transportation. It is also used to hold other objects together and protect objects during transport and storage.

Stretch film can come in a variety of specialty films. Some examples are UV stretch film, vented pallet wrap, anti-static stretch film, colored stretch film, etc.

How do I know what size of stretch film to use?

Different sized thicknesses and widths of the film for various applications will need to be considered. Use the chart below to find which thickness and width would be ideal for your application.

Suggested stretch film load limits are only to give a general idea of load capacity. They should not be construed as specification limits.

Click here to view our gauge conversion chart. For technical stretch wrap data, click here.

What is an equivalent stretch film?

Due to rising petroleum costs, stretch film manufacturers have made stronger, thinner stretch wrap. This thinner stretch film uses less petroleum resin during manufacturing, therefore costs less.

The equivalent stretch film uses a multi-layered technology to increase the strength of the film. Different manufacturers have different names for their equivalent films.

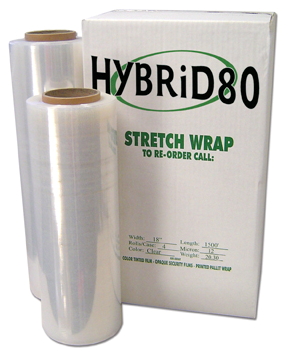

The two equivalent hand stretch films we offer are Hybrid stretch film and Micron stretch film.

We also provide our Performance line of machine stretch film that is thinner stronger and gives users the ability to save on costs.

Both hybrid and micron stretch film is considered an eco-friendly option for reducing film waste.

Hybrid stretch film is a thinner stretch film with a super-strong resin formula. It is the most lightweight film we offer, but it is not recommended for loads over 1800 lbs.

Because the film is thin, it does not have the same amount of tear resistance as a thicker film.

Micron stretch film is a film in-between the “true gauged” stretch film and the Hybrid stretch film. It is a multi-layered film that offers excellent cling, stretch, and tear resistance.

It provides users the ability to reduce costs while staying confident about load security.

Performance machine stretch film is our answer to rising machine stretch film costs.

The performance stretch film is a multi-layered machine stretch film that provides more stretch than traditional machine stretch film. It offers a high amount of cling and downsizing opportunity.

Are there any advantages to using opaque stretch film?

The opaque stretch film offers a variety of advantages over transparent stretch film. A few benefits include:

- Detours pilferage through valuable shipments by concealing products.

- It helps to protect products from UV Rays.

- Prevents damage caused by rain, dew, and dust.

- Outlasts regular transparent stretch film during extended outdoor storage.

- Great for color-coding products.

Do I need a UV stretch Film?

UV protection can help extend the life of the stretch film when stored in the sun. The use of an opaque UV stretch wrap can increase the storage life of the film and the product when stored outside.

Anyone should consider UV stretch for any shipments stored outside longer than 60 days.

Are shrink wrap and stretch film recyclable?

Both shrink wrap/film and stretch film/wrap are recyclable. Check with your local recycling center, and be sure they accept soft plastics.

Do I need a particular stretch wrap machine?

Stretch wrap machines are recommended for any business wrapping more than 15 loads per day. Stretch wrap machines help to reduce waste, increase efficiency, and promote a more secure and consistent load.

There are a variety of manual stretch film dispensers and products for businesses that stretch wrap less than 15 loads per day.

The Extended core stretch film is ready and easy to use out of the box. It is excellent for businesses that need stretch film, but do not ship many loads.

Two-handed manual stretch film dispensers are used because of ease of use, a built-in braking system, and the ability to tightly secure loads.

What is Pre Stretch Film?

Pre-stretch film or Pre-stretched film is a standard gauged stretch film stretched up to 90% of the film’s maximum stretch rate.

A standard 80 gauge stretch film becomes a 37 gauge stretch film after stretched 90%. The stretched film is rolled onto cores and requires little stretch during application.

How to stretch wrap a pallet?

Extract approximately a yard of plastic off the stretch film roll, squeeze 8 to 10 inches of the end together to form a rope shape.

Thread the rope part through one corner of the pallet. A knot is not necessary. Begin wrapping around the base of the pallet.

Wrap the bottom of the pallet at least five times while keeping the film tight as pulled off the roll. Slowly work your way up the box, focusing on maintaining a tight wrap.

The goal is to have all of the products stay together as one. Once at the top of the pallet, push the top boxes to see if they move or if they are one with the bottom boxes. If they move, wrap your way back down to the bottom of the pallet.